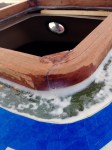

In pursuit of our watertight cabin goal, we decided to replace the original forward hatch with a Lewmar Ocean 60 Watertight Hatch. We built a mahogany combing to mount the hatch on a flush surface, and to avoid splash when the hatch is in its vented position. At first this hatch was difficult to close. So difficult we thought it faulty. However, with strength and weight focused on the handles at their attachment points, we can now close it with increasing ease (thank you James).

Author: briandeb

V-Berth

The original V-Berth left something to be desired: storage, comfort, style, etc. Some of the original cabinetry had been cut away to accommodate an obsolete holding tank, and the volume of available space was largely inaccessible with the previous compartment design. V-berth reconstruction was also a great opportunity to add structure and strengthen the forward third of the Dawn Treader. Its watertight integrity has been enhanced with new watertight compartments. The V-berth platform was also raised 8 inches above the waterline.

We are super excited to set up our sewing work area in the coming weeks! We’ve got foam, fabric, and a Sailrite Ultrafeed LSZ-1! Let the sewing lessons begin! We’ll see how things turn out…

Ventilation

Ventilation became a high priority after sailing in rougher weather to the Azores. The cabin was stale and claustrophobic! We now have three air-only ventilators (watertight even in a capsize). Two vent cowls were added for the main cabin, and one low profile vent with electric fan was installed for the head.

We also added a new hatch under our nesting dinghy. Because of its protected position, this Lewmar Ocean 30 stays open in most conditions (when the dinghy is stowed). In combination, the new air-only ventilators, small protected hatch, forward hatch, and companionway complement 4 original port holes and give Dawn Treader many ventilation options.

Electrical

The all new wiring in 2014 was installed in a couple of weeks. Brian created an electrical box consisting of circuit breakers, postive and negative busses, terminal strips, inverter, and solar charge controller.

We have now moved the electrical panel to the new navigation station, where the old ice box was!

Interior Paint

We painted interlux epoxy primekote on the interior cabin. We like the matte finish and high build easy application. Its also a hard durable finish that works inside (less vulnerable to sunlight), so we avoid the high-gloss, expensive, difficult to apply top coat perfection that we use outside.

We’ll be updating with more paint in the future, and this is a great base for almost anything we choose.

Head – Chart Room

The head was initially converted to a chart room in 2013. All the thru hulls were covered, a composting toilet was installed, and then moved to the V-berth.

We have now re-installed the head in this area, and moved the charting/navigation area to the location of the old icebox.

Jordan Series Drogue

For storm management we built a Jordan series drogue from a Sailrite kit. It consists of 107 cones and is deployed from the chainplates we fabricated and installed on the stern. The series drogue keeps the stern oriented to the weather.

Nesting Dinghy – Junior

Junior was born in 2013. He was built in Beaufort, North Carolina according to plans by Graham Byrnes.

After 2 years of sailing, Junior was ready for some TLC. His makeover was our first project upon return to the states in spring of 2015.

Check out this short video of Brian taking Junior apart in the water: Video: Nesting Dinghy, Quick Disassembly.

Exterior Paint

Our new spring 2014 deck paint was interlux perfection, and kiwi grip for non-skid. After our 2015 exterior construction projects, we’ll be painting again. We like the old saying…If it doesn’t move paint it, if it does move, give it a paintbrush.

Tiller Conversion

A previous owner of Dawn Treader had converted its tiller to rack and pinion wheel steering (bronze components and housing made this a heavy option). Simplicity, performance with wind vane, and weight reduction led us to change back to tiller. During the conversion, rotten deck core was replaced, vent cowls were sealed, a laminated tiller and new hardware (stainless steel cleats, main sheet wench, and main sheet blocks) were added.